Формы для литья под давлением можно разделить на различные категории в зависимости от их конструкции и использования. Ниже приведены распространенные классификации форм для литья под давлением :

Классификация по структуре:

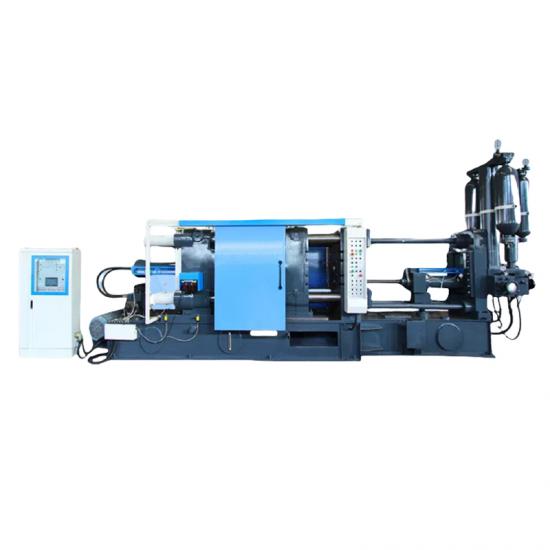

Матрица с холодной камерой: подходит для литья металлов с высокой температурой плавления, таких как алюминиевые сплавы , медные сплавы и т. д. В машине для литья под давлением с холодной камерой расплавленный металл подается через сопло в полость формы для отливки.

Матрица с горячей камерой: подходит для литья металлов с низкой температурой плавления, таких как цинковый сплав , магниевый сплав и т. д. В машине для литья под давлением с горячей камерой форма частично погружается в расплавленный металл, который выталкивается в полость формы с помощью плунжера.

Классифицируется по использованию:

Штамповочная матрица (обрезная матрица): матрица, используемая для вырезания формы отливки до окончательного размера.

Гидравлическая матрица: форма, используемая для приложения гидравлического давления в процессе литья под давлением для формирования отливок .

Литейная матрица: форма, используемая для впрыска расплавленного металла в процессе литья под давлением.

Классификация по форме и функциям:

Матрица с одной полостью: пресс-форма, которая может производить только одну деталь за раз.

Матрица с несколькими полостями: пресс-форма, которая может производить несколько одинаковых или разных деталей одновременно.

Литейная матрица: форма, используемая для контроля пути и скорости потока металлической жидкости в форму.

Core Pull Die: форма, используемая для извлечения деталей со сложной внутренней структурой в процессе литья под давлением .

Эти классификации являются лишь общими классификациями. В реальных условиях формы для литья под давлением можно настраивать и комбинировать в соответствии с различными производственными требованиями.